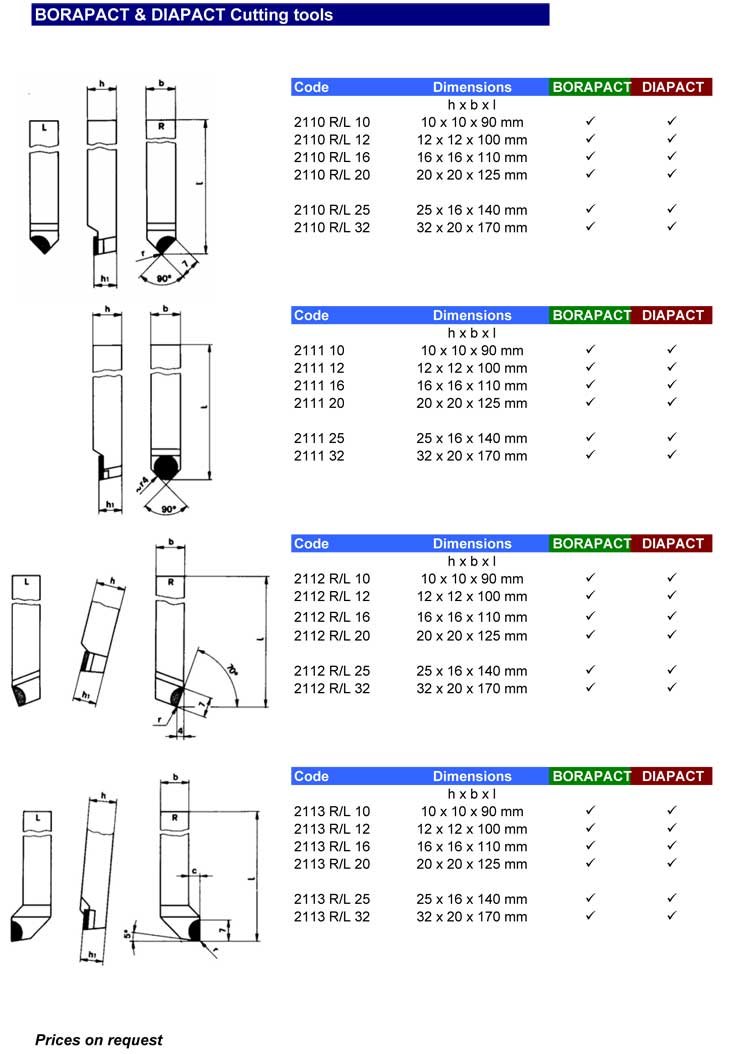

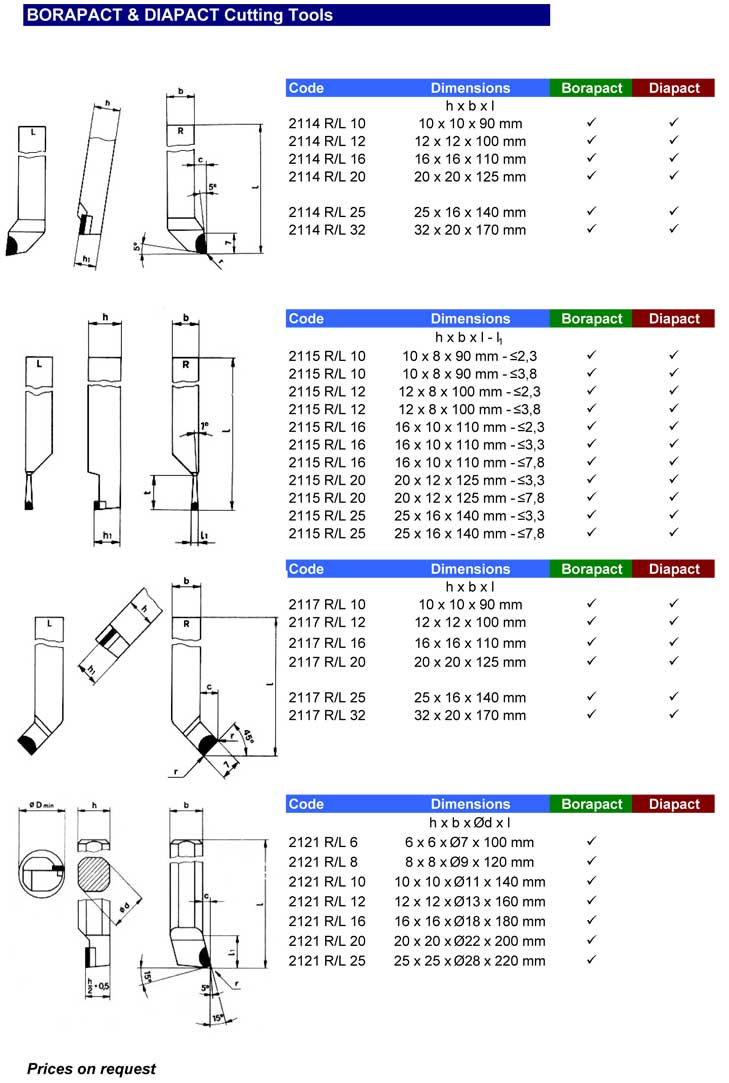

Metalworking - Diamond & CBN Turning Tools

|

|

Application Range: Operation conditions: Advantages: |

|

|

Application Range: Operation conditions: Advantages: |

|

|

|

|

|

|

|

|

|

|

|

|

Taylor Diamond Products | Taylor N.V. | Wechelsebaan, 62 | B-2275 Lille | Belgium

Tel: 0032 (0)475 41 57 58| E-mail: info@taylor.be